Email Support

Email Supportdomesticsales@legendsgroupin.com

Call Support

Call Support+91-99-1160-4653

Email Support

Email Support Call Support

Call SupportHome Products Wedge Wire Screens

Characteristics

Wedge Wire Screens

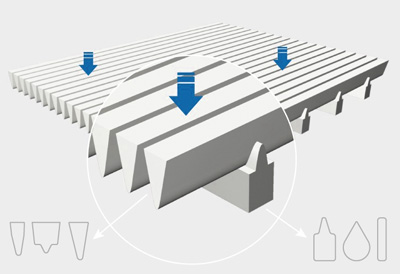

It is a sieve made from looped wires formed into a deep wedge-shaped section. Individual wedge wires are built into “panels " by threading cross rods of suitable diameter through the loops. The whole is then clamped and made secure usually by riveting or putting ring nuts over the cross rod ends or by welding.

The wedge wire screens can be supplied in various shapes and forms as per the requirements such as flat panels, curved sieve bends, conical baskets, cylinders, and troughs disks either in one piece or in segments. For curved, cylindrical and conical screens in most cases the cross rods lie along the circumference and profile wires run parallel to the axis. Occasionally this arrangement is reversed.

Owing to a greater wearing area being provided by hat top surfaces, wedge wire screens retain their aperture for a longer duration than round wire screens.