Email Support

Email Supportdomesticsales@legendsgroupin.com

Call Support

Call Support+91-99-1160-4653

Email Support

Email Support Call Support

Call SupportHome Products Sintered Mesh

Sintered Mesh

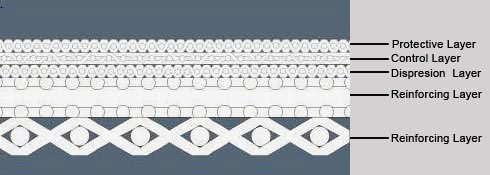

We provide stainless steel Multilayer Sintered Mesh, it is one standard combination 5-layer sintered wire mesh for the widest application. 5-layer different useless wire mesh made from stainless steel are brought together as per the different combination. They are sintered together through vacuum sinter compression and rolling and made into a kind of porous material.

Custom orders with gauges and sizes available.

Material

Material

Standard material is SUS316L (AISI316L).

Size

Standard size are 500×1000mm、600×1200mm, other sizes in the above-mentioned range are also available according to customer’s needs.

Our supplied multilayer sintered mesh & perforated metals are used in shifting and separation of food products and medical material, fine chemicals, powder materials and oil in air conveyors for powder material handling.

Filter elements for water, gas and oil filtration. The products are widely used in petroleum chemical industry, chemical fiber,metallurgy,pharmaceutics, electric power water treatment, foods and beverage etc.

We supply various filter Media like multilayer sintered mesh, Perforated Metals, wire products to support in making of various filter elements.

We supply various filter Media like multilayer sintered mesh, Perforated Metals, wire products to support in making of various filter elements.

We provide filter screens of various kinds for making automotive components & products, including muffler components, filter wraps and cages, grilles and guards.

Using of Perforated Metal adds more strength and pressure resistance in filter flow. Whether your filter needs range from sewage plants to seawater intake filters or small to large volume OEM production runs where materials from Air, sound, water to stones has to be filter, Micron opening filter elements & perforated metals are used as filters or screens itself in the screening of coal, gravel and ore your custom metal filters and strainers are always the most important part.

Stainless steel type 304/304l filter mesh

It is an austenitic, non-magnetic, thermally non hard enable economical stainless steel. It resists most oxidizing acids, filter cloth withstands all ordinary rusting, and is immune to foodstuffs, sterilizing solutions, most organic chemicals and dyestuffs, print cloth and a wide variety of organic chemicals, but resists poorly halogen acids.

Stainless Steel Type 316/316L Filter Mesh

It is similar to type 304 but distinguished primarily by the addition of molybdenum which significantly increases it's corrosion resistance. Type 316 can withstand corrosive attack by sodium and calcium brines, stainless steel filter cloth hypochlorite solutions, phosphoric, sulfurous, and acetic acids, and the hostile environment oft the body when used for implant

Stainless steel wire cloth is available in rolls or cutted into wire mesh discs and also as fabricated filter assembly. Woven wire mesh we are capable of processing the woven wire hardware cloth cloth into different shapes and sizes according to your request or drawings

1. Agricultural equipment.

Our products can be found in grain dryers, hammer mill screens, construction equipment, baskets, filters, guards and more.

2. Architecture.

Designers bring their ideas for building and parking structure facades to us. They design outdoor furniture, and components that bring beauty to all kinds of spaces. We execute their designs in many materials, including thick aluminum and steel.

3. Decorative patterns.

We make covers, guards, sunscreens, door, wall, and ceiling panels that are beautiful as well as functional. We can execute literally dozens of patterns.

4. Medical.

We make many components for the demanding medical field, including laboratory equipment like sterilizer racks and test tube holders

5. Perforated Metal Fabrication

Legends India Perforated Metal Sheet Factory can provide exact sheet sizes and exact side margins with rapid delivery. Whether the order is big or small, we will work with our customers to ensure low-cost and high-satisfaction.

Perforated metal sheets can be fabricated into filters, grills, sunshade panels and other products to meet the specific requirements of different applications.